Almost every house has some form of insulation installed – increasingly, however, builders and consumers are becoming savvier about what type of insulation they want. Insulation prevents heat from escaping the house, thereby helping the house to stay warm. Not only does this have major practical benefits – having a warm home is one of the basic requirements of having a liveable space – but it also has financial and environmental benefits.

Good insulation prevents you from paying to heat the air around your home. Retaining heat in your home will save your heating costs and ensure greater efficiency from the money you do spend. In addition, the fact that you use less fuel in heating lowers your overall carbon footprint, which is better for the environment.

This is the compelling case for insulating your home. Whether you are swayed by altruism or self-interest, either way, you need insulation.

This is where fiberglass comes in. Fiberglass is a material made from strands of glass, combined to make a reinforced plastic mat. Due to its insulating properties – as well as the fact it is lightweight and flexible – it is the most common fabric used in insulation.

Because of the growing desire for high-quality insulation, fiberglass has continued to grow in usage. Fiberglass is even used in car and aircraft parts.

in 2016, the global fiberglass market was $12.73 billion.

This guide will walk you through fiberglass in two of its most common forms – fiberglass roll and batt insulation – talking about what it is, how to use it, and what are its practical benefits. For more information on different types of insulation, see our guide on Blown-in Insulation and Spray Foam Insulation.

WHAT ARE FIBERGLASS

ROLL AND BATT INSULATION?

Many people have heard of fiberglass, but if you are going to install something in your home (or if you already have it installed), it’s important to know exactly what it is; after all, it wasn’t long ago that homes and commercial buildings were lined with asbestos.

What is fiberglass?

Fiberglass as a material was invented in the United States in the nineteenth century, but it wasn’t until the 1930s that mass production became possible. Fiberglass is created by shooting compressed air at molten glass. This creates small fibers that can then be woven or compacted together to make a sheet. This is then combined with a plastic resin to create a composite material.

Fiberglass has many properties that make it ideal for use in insulation. It has high tensile strength and compressive strength, yet can be combined into a multitude of shapes. Because it is both lightweight and strong, it can be used in a variety of applications, from boats to buildings.

Most importantly, it has extremely high insulating properties – heat cannot pass easily through sheets of fiberglass. This has led to its usage in homes and other buildings.

What is a fiberglass roll?

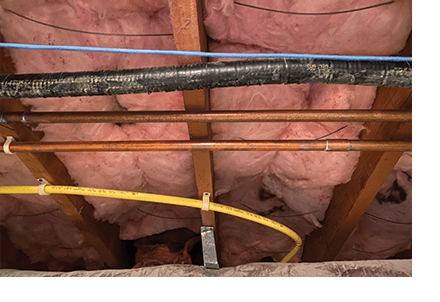

Fiberglass roll is one of several forms of fiberglass insulation. It is cut into sheets that are then rolled up. This makes installation easier. Fiberglass roll is particularly designed for covering large areas easily. All that’s required is to buy or cut the right width of roll (such as the width of the space between joists in the attic) and then you simply attach it at one end and unroll the fiberglass.

This is one of the most common types of fiberglass insulation.

What is batt insulation?

Batt insulation is very similar to rolls – the only difference being that batt insulation is cut to size in advance, and comes in sheets rather than a roll. These batts are installed in pieces, rather than being rolled out. In both cases, the fiberglass comes in sheets, allowing for easy installation.

With both batt insulation and rolls, you can buy either faced or unfaced. Faced insulation comes with a vapor retarder sheet on the outside (this is the paper-like material you sometimes see on insulation); unfaced material doesn’t have that, and therefore looks more ‘woolly.’

What are the other types of fiberglass insulation?

The other types of insulation are:

- Blown-in insulation

- Spray foam insulation

In both cases – as the name suggests – the fiberglass comes as small segments, which are sprayed into cavities using compressed air. For more information on this type of insulation, see our guides mentioned above.

What is R-value?

A critical metric when it comes to insulation is the R-value. This is the measure of thermal resistance, showing how well a material insulates. The climate you live in will determine what R-value you need. For more information on this, see our guide What is insulation R-value?

The table below shows the connection between R-value, insulation thickness, and overall cost.

| Thickness (inches) | R-Value | Cost (cents/sq. ft.) |

|---|---|---|

| 3 1/2″ | 11 | $.12 – $.16 |

| 3 5/8″ | 13 | $.12 – $.16 |

| 3 1/2″ (high density) | 15 | $.34 – $.40 |

| 6 – 6 1/4″ | 19 | $.27 – $.34 |

| 5 1/4 (high density) | 21 | $.33 – $.39 |

| 8 – 8 1/2″ | 25 | $.37 – $.45 |

| 8″ (high density) | 30 | $.45 – $.49 |

| 9 1/2″ (standard) | 30 | $.39 – $.43 |

| 12″ | 38 | $.55 – $.60 |

TIPS FOR INSTALLING FIBERGLASS

If you are thinking of installing fiberglass and you don’t want to hire a professional, then it is certainly possible for you to do it yourself without too much difficulty. For more information on the costs involved in these types of insulation, see our guide – Average Costs of Fiberglass Roll and Batt Insulation, which will walk you through the costs, including installation.

However, if you do decide to install the insulation yourself, you’ll need to follow the steps below:

PROTECTIVE EQUIPMENT

Although fiberglass may seem soft, it contains a number of small, sharp particles, which may damage your eyes or skin, causing severe irritation. As such, be sure to wear the following:

- Long pants

- Long sleeves on your arms (i.e. ensure your forearms are covered)

- Sturdy gloves

- Protective eyewear

- Face mask

MEASURE THE CAVITY

Before you even get close to installing the insulation, you need to measure the cavities you’ll be placing it in. Usually, this is between the joists or studs in your home. You can follow the rule that it’s better to measure twice and cut once, to make sure you don’t end up buying the wrong size.

You should also make sure that you don’t assume the spacing between the joists is consistent throughout your home – measure each one.

If you don’t measure correctly, you’ll end up leaving gaps, which defeats the purpose of installing the insulation in the first place. You should also be sure to measure the depth of the space, in order to buy the required thickness of insulation.

LAYING THE INSULATION

If you have insulation with facing on one side, be sure that the side with the facing ‘inwards’ (i.e. towards the liveable space). If you have a cavity that is not the standard shape, cut it with a knife – but be sure to leave no more than a half-inch gap between the joist or stud and the edge of the insulation.

Where you have items like cables, pipes, or electrical boxes, cut the insulation in half, and then place it around the items. You can then trim it further if necessary, although you should be careful not to cut any wiring that is under the area.

CHECKING YOUR WORK

Once you have installed the fiberglass, you should return at various times to see how it is functioning. If you have installed it in your attic space, for example, go up on a cold or windy day and see if you can feel drafts coming through gaps in the insulation – this will tell you where you need to patch up the spaces or add more insulation.

You should also inspect your insulation every year or so for wear and tear, and replace it where necessary.

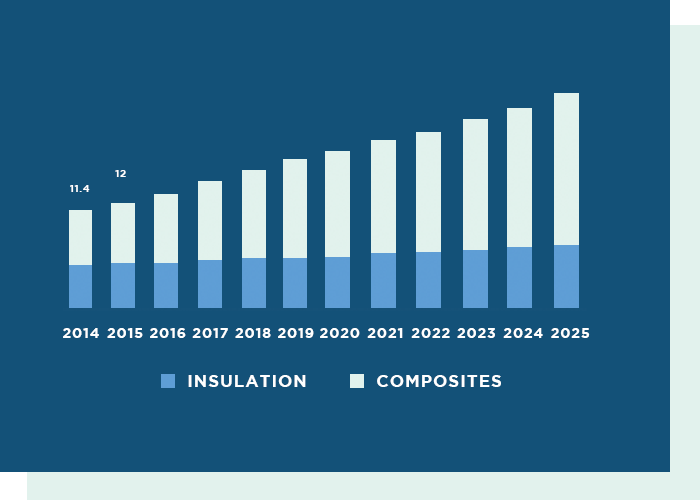

Fiberglass usage – in whatever form – is likely to grow in popularity in the future as technological developments increase.

One key factor is that it is becoming more popular in the building and construction industry, which will further increase investment into research and development, making fiberglass more effective and cheaper.

A trend in this respect is the growing use of composite fiberglass.

As the graph below shows, the insulation figures have remained constant (and are predicted to do so in the coming years), whereas the use of composite fiberglass is predicted to grow:

GLOBAL FIBERGLASS MARKET REVENUE

BY TYPE, 2014 – 2025 (USD BILLION)

So, driven by commercial investment, the future of fiberglass insulation is likely to be one of increasingly greater insulating properties, a drop in price, and ease of installation. This is good news for financially-savvy homeowners, who like the low prices and the savings on energy. It’s also good news for the environment, as less energy is wasted. All in all, the future looks bright for fiberglass insulation – whether in rolls or in batts.